What is IMR

IMR(In-mold Decoration by Roller), is a technology that prints decorative patterns and functional patterns on a film through a high-precision printing machine, and sends the film into a dedicated molding mold through a high-precision film feeding device for precise registering or positioning. After that, the patterns on the film will be transferred to the surface of plastic product through high temperature and high pressure of the injected plastic raw material. It is a technology that can achieve the integrated molding of decorative patterns and plastic material.

IMR Technological Advantages

-

Integrated molding

Integrated molding

Integrated molding simplifies the manufacturing process, reduces production/storage costs and labor hours, shortens product manufacturing cycles, and improves production efficiency.

-

Stable & Durable

Stable & Durable

Various reliability tests are at the highest level in the industry, ensuring product stability and durability.

-

High rate of non-defective goods

High rate of non-defective goods

Highly automated production ensures stable production and high yield of quality products.

-

Eco-friendly processing

Eco-friendly processing

Using automatic printing and eco-friendly ink, it meets environmental requirements.

-

3D relief texture

3D relief texture

Good decoration effect, which can combine multiple processes to enhance the three-dimensional texture of the pattern.

-

High adaptability

High adaptability

Injection molded products have the advantage of low deformation, especially for slender and thin wall workpieces. After molding, there is no need for molding and post processing, and it can also ensure no deformation, which can meet the requirements of 3D complex shapes

-

Beautiful and wear-resistant

Beautiful and wear-resistant

Surface hardening treatment, with wear-resistant and aesthetic characteristics.

-

Good coverage

Good coverage

Plastic molding products have good coverage and ink adhesion

-

High added value

High added value

High cost performance, low comprehensive cost, and can be widely used in large quantities and high value-added products.

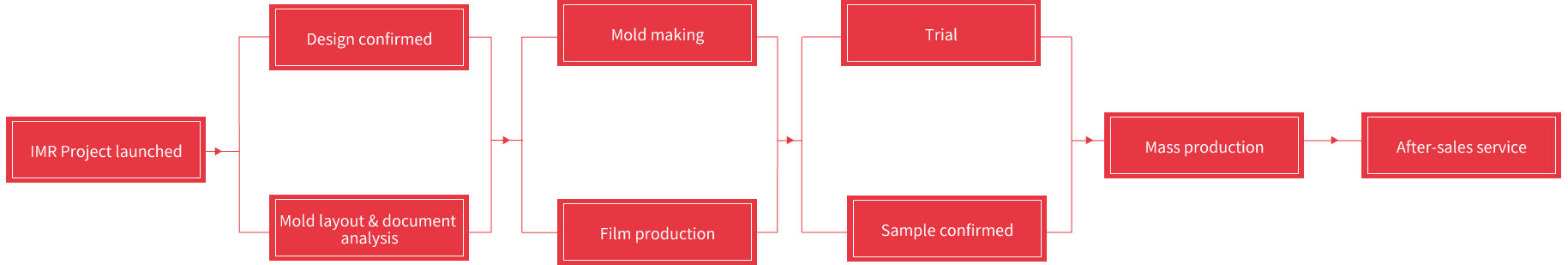

IMR Construction Method Flowcharts

IMR Production Process

1.Mold Making

2.Printing

3.Injection

4.Packaging & Delivery